Role of Gate Pass in Process Excellence in Manufacturing Industry

Manufacturing industries are great at innovations and have changed drastically and so have their supply chains. Today, these facilities need more than a paper log book and a friendly receptionist at the door. And solution to all this is an online gate pass.

Using gate passes will eliminate lengthy check-in processes and can monitor/handle visitors, equipment, work-in-process or finished products, trade secrets, data, and records, ensuring security compliance.

This blog will provide you with all the information you need to know about implementing an online gate pass for your supply chain and manufacturing industry.

Overview: Understanding The Role of Gate Pass In Manufacturing Industry

The gate pass system is becoming increasingly popular in manufacturing industries. The future of VMS is expanding as it can benefit from automated processes that save time and money. Onestop Cloud Based Digital/ online gate pass monitors the ongoing movement of vehicles and visitors in and out of your facility, securing your workplace while also offering a smooth check-in experience.

Additionally, it ensures that visitors are properly managed and tracked. It further benefits to collect check-in data and run instant reports to complete internal or third-party audits. The visitor management system also helps cultivate relationships that may generate business growth by automating follow-up communications between visitors and staff members to ensure you don’t lose important connections, reduce contact information errors that often result from traditional paperwork, and analyze strategic initiatives in supply chain efficiencies, product development, and inventory management. With all these benefits, it’s no wonder why so many manufacturing industries are choosing to implement Gate Pass or Visitor management systems in their businesses.

Before moving ahead, lets first understand what is process excellence in the manufacturing industry.

What Is Process Excellence in The Manufacturing Industry?

Process excellence for any manufacturing industry means creating effective, efficient processes through design and testing to deliver consistent and positive outcomes with minimal variation and waste. This process helps the industry to run smoothly and achieve pre-defined results consistently. It is all about improving the business working way to deliver value to their customers.

To achieve this, the supply chain of industry should also be flawless.

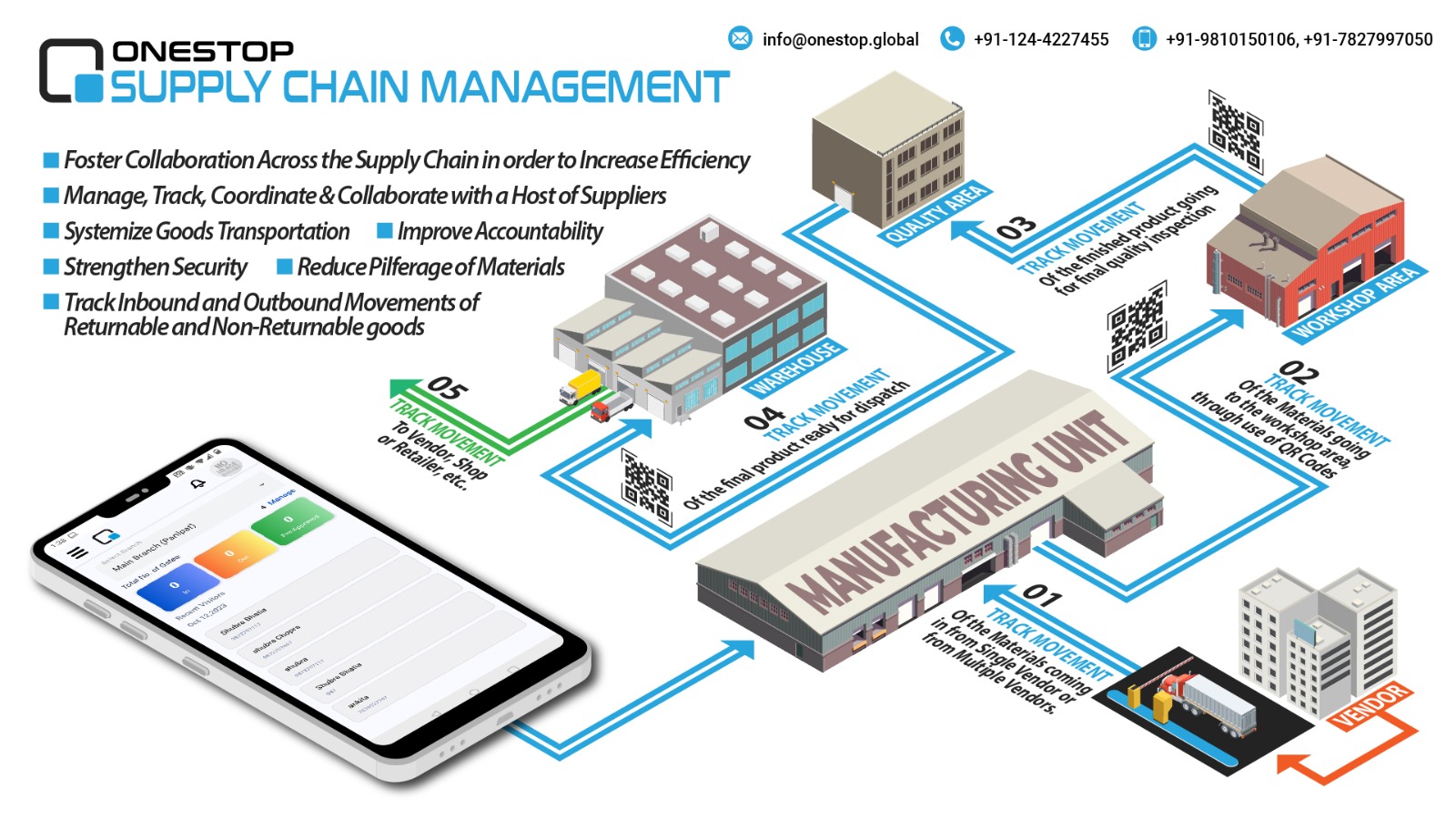

What is Supply Chain Management in the Manufacturing Industry?

The supply chain is the heart of any manufacturing industry. It is a network of interconnected businesses that work together to make products and deliver them to customers cost-effectively and professionally. It is a challenging task to manage and optimize large network of suppliers, securing raw materials and fulfilling orders.

Supply chain management works similarly to a material management system as it also takes care of everything from negotiating vendor contracts to inventory management to product shipping and returns. Thus, effective supply chain management is a necessity for manufacturing companies.

That’s why manufacturers invest in modern supply chain technologies to balance costs, quality, agility, and speed for the manufacturing process. According to a 2022 report by the World Manufacturing Foundation, manufacturing industries were the hardest hit by supply chain disruptions, with more than 60% of manufacturers experiencing supplier delays. So, to overcome this situation, companies opt for visitor management software that can optimize their overall operations.

How Supply Chain Contributes to Process Excellence?

Recently, 82% of CEOs planned to invest in supply chain systems to achieve process excellence. This is how the supply chain contributes in achieving process excellence:

- Improved Planning

To achieve process excellence, planning is most important. Effective decision-making in the supply chain is done through advanced forecasting approaches such as predictive analytics and closed-loop planning to enhance customer satisfaction and services. All the upside and downside potential is considered along with advanced inventory management approaches to optimize inventory levels and minimize stock-outs or excess inventory, resulting in improved supply chain efficiency and profitability.

- Enhances Performance Management

In supply chain, performance management can be enhanced by integrating data from all suppliers and service partners. Organizations can achieve informed decision-making to maximize efficiency and effectiveness, lowering operational costs while improving customer satisfaction. According to a prediction, organizations can experience up to 30% lower operational costs and a reduction of 75% in lost sales.

- Automation

Manufacturing industries are switching more to automated processes to improve accuracy and speed. The automated processes helps in handling materials from receiving and unloading to picking, packing, and shipping. It decreases costs, increases productivity, and minimizes error rates.

So, the proper planning, automation, contribute to process excellence. And by relying on a reliable material gate pass system its increases the process excellence. The system automates the entry exit process, enhance safety & security for safeguarding personnel, materials, and vehicles, keeps track of to and fro of material from vendors to suppliers and vice versa, manages returnable (RGP) and non returnable gate pass.

How Does Gate Pass Help In Process Excellence In The Manufacturing Industry?

For manufacturing industries, achieving process excellence and having the flawless supply chain can be a daunting task. From building a strong relationship with suppliers & vendors, to shipping, and delivery, all need strategic planning & complete tracking. And here an online Gate Pass acts as a savior. Let’s explore how:

- Only Allow Registered or Pre-Authorised Vehicles

The gate pass system allows you to load all your drivers and vehicles onto the platform by assigning order numbers with a validity period and the number of entries allowed per day.

Also, if any vehicle arrives on campus, it needs to pass the scan. If the details are not recorded in the system, the access is denied automatically.

- Collect Relevant Information

A reliable gate pass system records different mandatory information such as if a vehicle is delivering raw material, it captures the delivery note and reg numbers, or the reason for entry and what material the vehicle is carrying. It will also maintain a cloud-secure record of drivers details such as citizenship verification, and document requirements, and easily print visitor badges for quick identification.

- Pre Register Gate Pass

To digitally automate entry and exit, pre-registration of gate passes is required. Onestop Gate Pass Management System offers real-time notifications. You can pre-register two types of gate passes through the dashboard.

- Returnable Gate Pass: A returnable gate pass is issued for materials that enter or exit and are returned or have to be sent back.

- Non Returnable Gate Pass: A non returnable gate pass is issued for materials that enter the gates of your facility and do not exit or exit your premises and are not to be returned.

- Seal Capturing

Another important feature of supply chain management is seal capturing in which the gate pass system helps to bolster product control and supply chain security. It allows you to scan a seal to keep track of materials. The system will send automatic notifications when a specific seal number enters or exits your campus.

- Monitoring and Reporting

Overall a strong gatepass system will improve compliance and manufacturing industry intelligence. In other words, it will keep track of how long vehicles stay on site, record incidents and create financial reports while ensuring security compliance that can be completely customized for the needs of your particular manufacturing facility. Currently, 81% of supply chain professionals believe that analytics and reporting will be important for reducing landed costs and improving overall supply chain efficiency.

Conclusion

If your facilities are still relying on legacy systems, they’re not likely able to keep up. And those who continue to use outdated technology make their enterprises vulnerable to attack. So, it’s time to upgrade from your legacy systems to a seamless, efficient, and scalable visitor management system.

Investing in OneStop visitor management software, you can ensure that your manufacturing industry is safe from any potential security threats while still providing an enjoyable experience for everyone who visits. It is highly configurable and easy to tailor and integrate it into your supply chain security protocols. After all, services are up and running, and the number of workers and visitors is ever-increasing.

Leave a Reply